- Lincoln Site - est. 1842

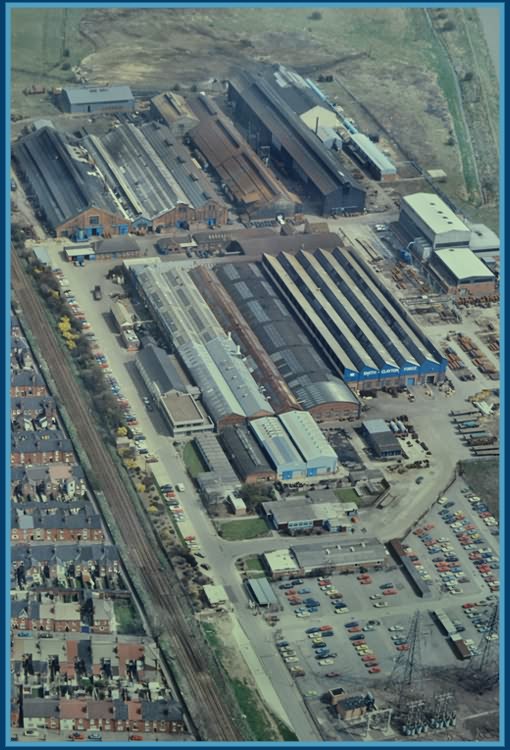

- Sheffield Site - est. 1869

Clayton and Shuttleworth Ltd was established in 1842 to produce agricultural equipment, specialising in threshing machines. The Company continued to progress and expanded its business to manufacture railway rolling stock, goods wagons and aeroplanes. During this time new sites were also acquired in Lincoln and at the Government's request the Abbey Works was built. This site produced Handley Page bombers and Vickers Vimys during World War 1.

After the war the Company continued to produce railway carriages and wagons and diversified into crankshafts, axles and other general engineering forgings. In the late 1920’s the Company faced difficulties and parts of the business were either sold or closed. In 1929 Smith – Clayton Forge Ltd was formed in conjunction with the parent Company, Smiths of Coventry. It was not until 1935 that the Lincoln site saw an upturn and at this time it started to produce forgings for the motor car and aircraft industries, with customers such as Rolls Royce.

Prior to, and during World War 2, the forge was producing airscrew shafts and crankshafts for Rolls Royce engines, which powered the Hurricanes, Spitfires and Mosquito aeroplanes, which played a major part in the war effort.

After the war a lot of money was invested in development and updating the equipment and consequently the Company prospered. In 1951, after the introduction of new machinery, the Company started to produce crankshafts for heavy commercial vehicles and connecting rods for diesel locomotives. During the late 1950’s, due to the skills of its employees, the Company played a part in the development of the modern gas turbine (jet engine).

During the next 40 years there were a number of new owners and changes to the business. In 1963 the Company was sold to GKN forgings and shortly after was amalgamated with British Steel Special Steels Division to form UES. During the 1970’s and 1980’s developments of the site continued and the Company was split into 2 divisions, UEF Automotive, producing crankshafts, and UEF Aerospace. In 1995 GKN Holdings was sold entirely to British Steel and the Company became part of the British Steels Forgings Group.

In November 2001 the Lincoln site, along with UEF Automotive – Sheffield, were purchased by an Italian Company, who formed Bifrangi UK Ltd, our current owners.

Ambrose Shardlow was first founded in 1869 as a general engineering and machining company based in Attercliffe, Sheffield.

In 1900 the company began to specialise in the production of crankshafts. In 1916 the demands were such that the company purchased more land for a new factory in Grange Mill Lane Meadowhall. Three heavy drop stamp hammers were installed together with heat treatment and all the equipment necessary for forging.

By 1920 the firm had expanded and became a Public Limited Company but the depression was looming. Shardlow’s were fortunate in that they had won a contract to provide the whole of Ford UK’s requirements. Shardlow’s was expanding at a time when most were contracting. The following years saw a revival in the fortunes of the motor industry and Shardlow’s prospered.

In 1930 the drop forging and machining capabilities were doubled and doubled again in 1933. At this time the whole of the manufacturing was transferred from Washford Road to Meadowhall.

In 1939 Shardlows had 21 production hammers and a small one that was used by their own engineers. Until the war, superstition prevented there being a number 13. During the Dunkirk evacuation a German hammer was discovered crated up on the dockside. This was shipped back to England where the then Ministry of Supply ordered it to be installed at Shardlow’s. This became Hammer No 13 and was still in operation until the forge was closed in the 1980’s. By 1940 Shardlows employed 450 people and were producing 200,000 crankshafts annually. Throughout the war Shardlow’s were a key producer of crankshafts for aircraft and military vehicles

In the period 1950-1960 Shardlow’s continued to thrive and employed around 2,200 staff. They produced crankshafts for English Electric, Rolls Royce, Dorman, Napier and Paxman engines which were fitted to many military vehicles and ships. In 1963 Guest, Keen and Nettlefolds (GKN) obtained a 49% share in the company and Shardlows became part of the largest engineering organisation in the country.

Shardlows remained a part of GKN until 1986 when the forging division of GKN was taken over by British Steel. Now a crankshaft machining company, the forging operations having been transferred to Lincoln, two further ownership changes occurred in 1995 and 1997. In November 2001 the company was brought by Bifrangi, an Italian forging company who amalgamated the Sheffield and Lincoln sites to form Bifrangi UK Ltd.